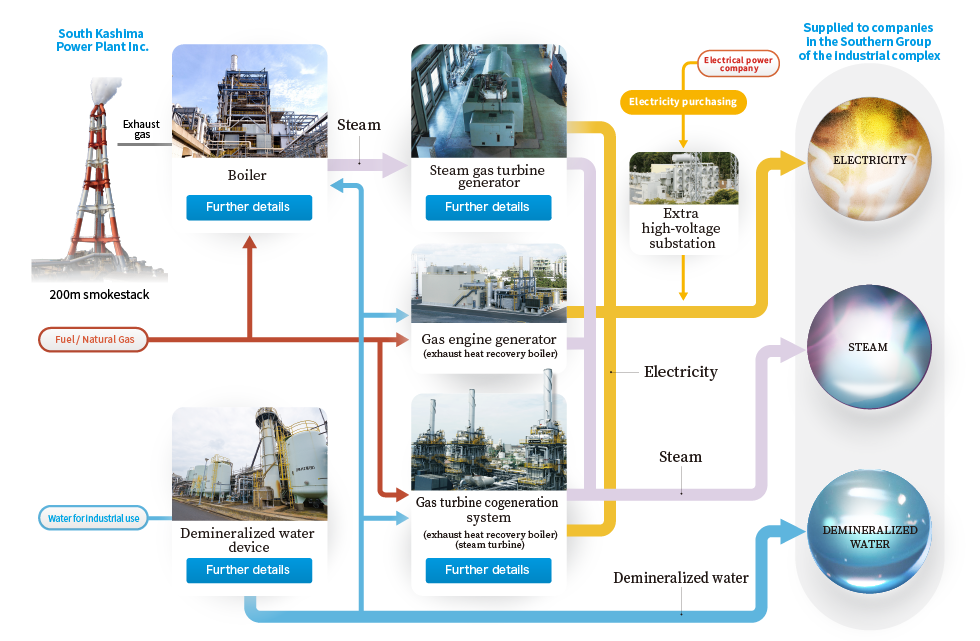

Boilers

Boilers are devices that use fire, high-temperature gas, electricity or other elements as a source of energy for boiling water to create hot water or steam. South Kashima Power Plant Inc. uses the combustion heat from Natural Gas as a source for heating and generating steam. The steam is generated by applying the heat from the flames of Natural Gas to thin water pipes that pass through water. Applying additional heat (superheating) to this steam turns it into high-temperature, high-pressure steam, which is then supplied to each company for generating electricity. Our boilers have been modified to use the heat from exhaust gas to heat the air used for combustion purposes so that each company is able to use heat energy efficiently, and this has enabled us to achieve high energy efficiency rates.

Gas Turbine

Cogeneration Systems

These systems consist of gas turbine generators and exhaust heat recovery generators. The turbines and generators in gas turbine generators are directly rotated through the combustion of Natural Gas to generate electricity. Heat recovery generators recover the heat energy from exhaust gas after the gas turbines have been rotated to create steam with heat recovery boilers, which is then used to generate electricity and steam with steam boiler generators. This enables extremely high levels of generation efficiency compared to conventional steam turbine generators.

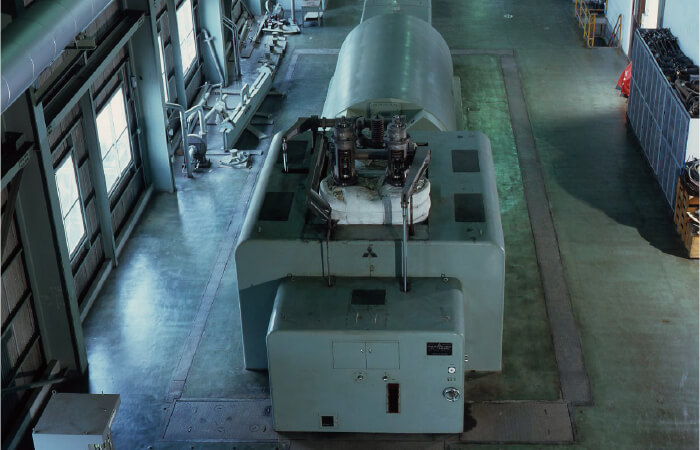

Steam Turbine Generators

The steam generated by boilers is used to operate turbine generators and create electricity. South Kashima Power Plant Inc. operates two types of turbines: condensing turbines and back-pressure turbines. Condensing turbines cool the steam from the turbines in condensers to return it to water. Returning steam vapor to liquid water creates an almost-perfect vacuum within the condenser, which helps withdraw the exhaust from the turbine and enhances rotational driving forces, thereby increasing power generation efficiency. Back-pressure turbines use pressure levels that are higher than atmospheric pressure to withdraw and use the turbine exhaust as steam. Steam is used by client companies as a source of heat, and the overall energy efficiency from these turbines is higher than that available from condensing turbines.

Demineralized Water Devices

We receive water for industrial purposes from Kitaura (lake), but this includes algae, saline and other impurities. These impurities will not evaporate if the water is supplied directly to the boilers without treatment, and this would result in scale (contaminants) adhering to the boiler’s evaporation pipes. Not only are the efficiency rates of boilers reduced if scale is apparent, it also reduces the life-expectancy of the facilities. We therefore manufacture demineralized water from which all impurities have been thoroughly removed with the use of filters, flotation equipment and ion-exchange resin. The demineralized water we produce is not only used for supplying our boilers, but also supplied directly to other companies.